High-Resolution Fiber-Optic Ultrasonic 'CT' Assists in Full-Lifecycle Analysis of Lithium Battery Health Evolution

In the future, the commercial usage can be realized when sensor array and artificial intelligence technology are adopted.

CHENGDU, SICHUAN, CHINA, May 30, 2025 /EINPresswire.com/ -- In recent years, with the rapid development of the new energy vehicle industry, the endurance and energy density of lithium batteries have been significantly improved. However, this advancement has correspondingly increased the risks associated with battery failures. Consequently, implementing safety failure analysis and early warning mechanisms for lithium batteries has become critically important. Conducting dynamic analysis of the entire lifecycle process – including encapsulation, electrolyte filling, charging/discharging, and damage – can effectively guide battery manufacturing and usage practices, thereby advancing next-generation battery development.Current battery health monitoring methodologies encompass solutions such as radiography, thermal imaging, ultrasonic testing, and internal stress detection. Among these, ultrasound technology stands out as an exceptionally suitable "CT" imaging tool for lithium batteries due to its superior penetration capability, rapid response speed, high spatial resolution, and real-time monitoring capacity, which enable distinct responses to various internal evolution processes. Notably, fiber-optic ultrasound solutions, in particular, offer miniaturization, high sensitivity, resolution, and penetration depth, positioning them as a promising technology for battery diagnostics.

To address lithium battery safety inspection requirements, the research group of Professor Qizhen Sun and Postdoctoral Researcher Hao Li from the School of Optical and Electronic Information at Huazhong University of Science and Technology (HUST), in collaboration with Professor Zhen Li from the School of Materials Science and Engineering of HUST, has developed a visual inspection solution utilizing a fiber-optic ultrasonic imaging system. As illustrated in Figure 1(a), the ultrasonic battery detection mechanism operates by monitoring variations in time of flight (ToF) and intensity of transmitted ultrasound waves when structural changes occur within the battery, enabling precise localization of defective areas through regional scanning.

Through in-depth investigation of lithium battery structures and ultrasound propagation characteristics, researchers have identified that ultrasound signals in the hundreds of kilohertz range simultaneously offer high resolution and significant penetration depth. Leveraging this discovery, the team developed a high-sensitivity fiber-optic ultrasound sensor based on a glass-diaphragm vibration Fabry-Perot interferometer (FPI), as depicted in Figure 1(b). Through optimized diaphragm dimension design, the sensor achieves highly sensitive ultrasound detection within the 500 kHz frequency band. Demonstrating exceptional performance metrics, the sensor attains a signal-to-noise ratio (SNR) of 52.8 dB for ultrasound signals at 27.73 Pa acoustic pressure, with a excellent noise-equivalent sound pressure (NEP) as low as 63.5 mPa. This represents nearly two orders of magnitude reduction in noise levels compared to conventional electrical sensors. Furthermore, capitalizing on the diaphragm vibration mechanism, the device achieves a remarkable sensitivity of 0.558 V/kPa, significantly outperforming traditional end-face fiber-optic sensors. The combined advantages of ultra-low NEP and high sensitivity enable precision visualization of internal battery structural variations, providing critical technical support for advanced battery health monitoring applications.

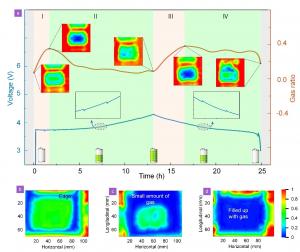

Ultrasonic imaging was performed on the acrylic plate (Fig. 1(e)) using the described system. As demonstrated in Fig. 1(f), the air slit with the width of 0.5 mm was clearly resolved. Further, researchers conducted visualized analysis of solid electrolyte interface (SEI) formation in anode-free lithium batteries during the formation stage (initial charge-discharge cycle). The charge-discharge voltage profile and gas evolution curve are shown in Figure 3(a), where gas distribution variation during the charging phase exhibits an initial increase followed by a rapid decrease, corresponding to the SEI formation process. Furthermore, the system achieved precise imaging differentiation of lithium iron phosphate batteries (LFP||Gr) under varying states of health (SOH), as demonstrated in Figures 3(b)-3(d). The battery health status progressively deteriorates from left to right in these imaging results.

This work pioneers the visualization of internal gas evolution and electrolyte wetting status in batteries through fiber-optic ultrasonic sensing by integrating ultrasonic "CT" imaging with battery diagnostics. The study developed a high-performance fiber-optic ultrasonic sensor, successfully implementing health monitoring for lithium iron phosphate (LFP) batteries and anode-free lithium metal batteries, thereby providing a novel approach for future battery production and performance monitoring.

The research team of Intelligence Lab on X-fiber (iF-Lab) at Huazhong University of Science and Technology is supported by the National Engineering Research Center of Next Generation Internet Access-system. This team is dedicated to research on micro-nano structured optical fiber sensing technologies and their applications, including micro-nano structured specialty optical fibers and devices, distributed optical fiber sensing technology, all-fiber ultrasonic transducer and imaging technology, ultrafast laser precision measurement technology, and their applications in large-scale engineering and health monitoring (Research Team Website: http://mnofs.oei.hust.edu.cn/index.htm). Professor Sun Qizhen, the team leader, has won the National Science Fund for Distinguished Young Scholars and Excellent Young Scientists Fund, and was granted by the EU Marie Curie Fellow, and Hubei Province Innovation Group. The team has undertaken over 20 national-level projects, including NSFC (Distinguished Young Scholars, Excellent Young Scientists fund, Key Project, Joint Fund for Regional Innovation and Development, General Project, and Young Scientists fund), key research and development projects and instruments projects from the Ministry of Science and Technology, etc. The team has successfully transferred and applied patent technologies related to fiber-optic acoustic sensing. The team has been authored/co-authored over 120 academic papers in the leading scholarly journals in optical field, including Opto-Electronics Advances, Light: Science and Applications, PhotoniX, Optica, Photonics Research, Advanced Science, etc., and has been authorized 47 invention patents. The corresponding research achievements have been applied in many fields and recognized by several awards, including the first prize for technical invention of China Society of Communications, the first prize for innovative products of the Chinese Society of Optical Engineering and the gold medal of the Geneva International invention Exhibition, etc.

Andrew Smith

Charlesworth

+44 7753 374162

marketing@charlesworth-group.com

Visit us on social media:

LinkedIn

YouTube

Distribution channels: Book Publishing Industry, Electronics Industry, Science, Technology, Telecommunications

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release